Gas fittings play an essential role in lots of different applications, ensuring the safe and efficient transport of gas for everything from camping stoves to industrial machinery.

Understanding the types of fittings available and their specific uses can help you choose the right one for your needs and keep things safe. In this guide, we’ll explore the different types of gas fittings and highlight how they’re used.

What are gas fittings?

Gas fittings are components that connect gas lines, cylinders or appliances to ensure a secure and leak-free flow of gas. These fittings include regulators, valves, connectors and adapters. They are designed to handle different types of gas, such as propane, butane or natural gas, and cater to varying pressure requirements.

You can find a variety of different types of gas fittings in our kits, such as our Oxygen Propane Propylene HD Gas Heating Kit. This contains regulators, gas connectors and valves, as well as arrestors, hose and nozzles.

Types of gas fittings

To understand gas fittings in a bit more detail, let’s take a look at the different types of gas fittings applications. Understanding how they’re used can help you to recognise when you need to replace certain components.

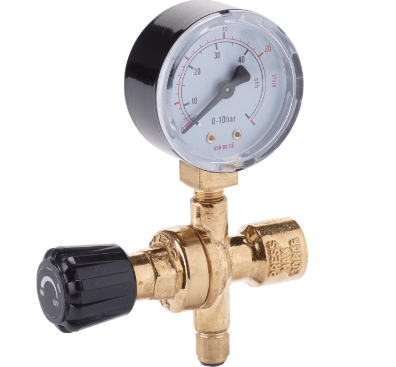

1. Gas regulators

Regulators, like the Clip On Butane Regulator with Pressure Gauge, control the pressure of gas flowing from a cylinder to an appliance. They ensure that the gas pressure remains consistent and safe for use. For example, low pressure regulators are used for barbeques and patio heaters, whereas high pressure regulators are more commonly used in industrial burners and heavy-duty equipment.

2. Valves

Valves are critical for controlling the flow of gas, allowing users to turn the gas supply on or off. Ball valves are used for quick shutoff in emergency situations, and needle valves for precise control in laboratory or medical equipment.

3. Gas connectors

Gas connectors link gas cylinders to appliances, ensuring a secure and flexible connection. They come in a variety of different materials, such as rubber or stainless steel, to suit different environments.

4. Adapters

Adapters enable compatibility between different gas fittings or appliances. For instance, an adapter might allow a propane fitting such as a regulator to connect to butane fittings – but it’s important that you know what you’re doing.

Applications of gas fittings

Gas fittings are used for a variety of different things. They’re used in camping and outdoor cooking to make things more comfortable. Regulators and connectors are vital for setting up portable stoves or BBQs, ensuring a steady and safe gas supply.

In homes, gas fittings connect heaters and boilers to their gas supply, maintaining efficient performance. Portable heaters often use regulators to ensure the correct gas pressure.

Industries rely on high-pressure regulators and durable connectors for equipment like blowtorches, kilns and furnaces too. Safety valves also play a crucial role in preventing accidents in high-stakes environments. Gas fittings are integral to backup power systems that run on gas generators. Reliable connectors and regulators ensure that these systems perform seamlessly during outages.

Choosing the right gas fitting

Selecting the right gas fitting is important for safety, efficiency and performance. One of the primary considerations is the type of gas you’ll be using. Different fittings are designed to work with specific gases, such as propane, butane or natural gas, and making sure fittings are compatible is essential – carefully check the manufacturer’s specifications to confirm the fitting is suitable for the gas type.

Pressure requirements are another critical factor. Gas appliances operate at specific pressures, and your fittings must match these requirements to ensure proper operation. For instance, a regulator or valve not designed for your appliance’s pressure needs can result in underperformance or even dangerous overpressure. When selecting your fitting, verify the pressure rating and make sure it aligns with your appliance to maintain functionality and safety.

Consider the environment in which the fitting will be used too. Materials and coatings play a role in durability, especially in challenging conditions. For outdoor setups, choose weather-resistant materials like stainless steel or brass, which can withstand exposure to moisture and temperature fluctuations. For indoor or industrial use, assess the environmental factors such as humidity, temperature extremes, or exposure to chemicals, and choose fittings designed to handle these conditions.

Prioritising the right material for your setting not only ensures longevity but also minimises maintenance needs over time.

Safety tips for using gas fittings

Using gas fittings safely is essential to prevent accidents, leaks and other hazards. Here are some important safety tips to follow:

• Choose the right fitting – always ensure the gas fitting is compatible with the type of gas and meets the pressure requirements of your appliance. Using the wrong fitting can lead to leaks or malfunctions.

• Inspect for damage – regularly check gas fittings for cracks, corrosion or wear. Damaged fittings should be replaced immediately to prevent leaks or failures.

• Install correctly – ensure all fittings are securely tightened but avoid over-tightening, as this can damage the connection. Use the right tools and follow manufacturer instructions for installation.

• Use thread sealant – if needed, apply gas-safe thread sealant or tape to threaded connections to ensure a secure, leak-proof seal. Always use products specifically designed for gas fittings.

• Test for leaks – after installation, test for leaks using soapy water applied to the connections. Look for bubbles, which indicate a leak, and address any issues before use.

• Ensure proper ventilation – gas appliances and fittings should be used in well-ventilated areas to prevent gas build-up, which could lead to fire or explosion hazards.

• Avoid sparks and flames – keep open flames, cigarettes and sparks away from gas fittings during installation, maintenance, or repairs to prevent accidental ignition.

• Turn off the gas supply – always shut off the gas supply before working on fittings or appliances to reduce the risk of leaks or accidents.

• Perform regular maintenance – schedule inspections by a qualified technician to keep your gas fittings and appliances in safe working condition.